|

1 2 3 4 5

304 201 316 430 Stainless Steel Sheets Manufacturer

China Decorative Stainless Steel Sheet Factory

China Mirror Polished Stainless Steel Sheets

Pvd Color Coating Stainless Steel Sheet Suppliers

China Etched Stainless Steel Sheets Manufactures

|

304 201 316 430 Stainless Steel Sheets Manufacturer |

China Decorative Stainless Steel Sheet Factory |

China Mirror Polished Stainless Steel Sheets |

Pvd Color Coating Stainless Steel Sheet Suppliers |

China Etched Stainless Steel Sheets Manufactures |

|

1 2 3 4 5

China Black Stainless Steel Sheets Suppliers

China Embossed Stainless Steel Sheet Manufacturers

China Decorative Stainless Steel Sheet Suppliers

China Mirror Finish Stainless Steel Sheet

China AISI 316 Stainless Steel Sheet

|

China Black Stainless Steel Sheets Suppliers |

China Embossed Stainless Steel Sheet Manufacturers |

China Decorative Stainless Steel Sheet Suppliers |

China Mirror Finish Stainless Steel Sheet |

China AISI 316 Stainless Steel Sheet |

|

1 2 3 4 5

China Stainless Steel Metal Fabrication

China sheet Metal Fabrication Factory

Laser Cut Stainless Steel Screen Factory

China Stainless Steel Fabrication

China Architectural Metal Fabrication

|

China Stainless Steel Metal Fabrication |

China sheet Metal Fabrication Factory |

Laser Cut Stainless Steel Screen Factory |

China Stainless Steel Fabrication |

China Architectural Metal Fabrication |

Working principles:

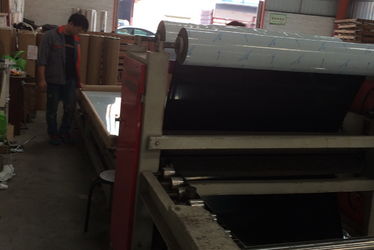

CNC laser cutting is a process where a computer-guided industrial laser cuts sheet material by vaporizing the cut path of the workpiece, achieving the desired shape. our innovative pulsed laser technology which allows for accurate cutting of sheet metal. Commonly cut metals include stainless steel, mild steel and aluminum.

Need parts laser cut quickly for your business or project? Get started today with a quote!

Working principles:

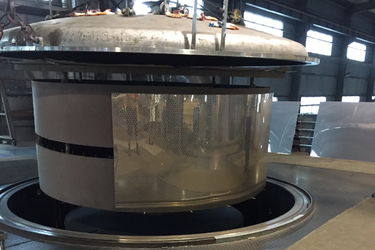

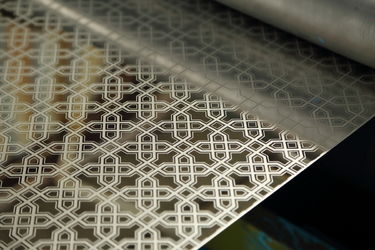

Stainless steel embossed sheet, also known as "water ripple stainless steel sheet","3D stainless steel sheet", is a new concept sheet, which has strong three-dimensional effect. It is processed by embossing stainless steel sheets with machinery so that concave-convex patterns are made (dozens of patterns available).

![]()

![]()

Working principles:

Mirror finish is created by mechanically treating the surface with a series of progressively finer abrasives. Alternatively a special rolling procedure is used which can simulate the appearance of mechanical abrasion. For this stage, it is essential to remove deep scratches as any surface defects will be very noticeable on the finished product. The final process involves buffing the surface for 5-10 minutes to create a mirror-like, highly reflective finish.

![]()

![]()

Working principles:

The coloring of stainless steel can be achieved by chemical surface treatment which actually modifies the surface oxide film on the metal. The colored finish is attractive but susceptible to finger-marks, which results in a color change and is not hard-wearing, and this should be considered when deciding on the use. The process uses acidic solution which, due to the variances in composition of the stainless and the process variables, can be guaranteed to be the same every time.

![]()

![]()

Working principles:

PVD is the abbreviation of Physical Vapor Deposition. It is a process carried out in high vacuum at temperatures between 150 and 500 .PVD stands for Physical Vapor Deposition, which refers to under the condition of vacuum, use Physical method to make material preparation technology of thin film deposited on the plated , A range of colors are available, including gold, black, bronze, blue and so on.

![]()

![]()

![]()

![]()

![]()

![]()